Water supply system filter timing automatic backwash technology

Fu Changwei, Tian Lin, Yang Qingyun, Tang Weikai, Shu Qin

(Wuhan Iron and Steel Power Plant, Wuhan 430080, China)

Abstract: The original backwashing mode of filter group in cold rolling water treatment workshop of energy complex plant is designed in direct drainage mode, which does not adapt to the newly added backwashing water local reuse system, affects its continuous operation and water quality standard, and reduces the backwashing water reuse rate. The automatic backwashing control program of filter group of each water station in cold rolling water treatment workshop was modified, the timing start function was added, and the number of backwashing stations and the total length of backwashing time could be controlled. The backwashing interval of a single filter could be adjusted, so that the filtration and backwashing time could match with the local recycling treatment capacity of backwashing, and the operation continuity and stability of the backwashing water treatment system could be improved. The water recycling rate is improved and the new water consumption is reduced.

Key words: filter backwash; Start on time; Process improvement

Filter is an important production equipment for reducing raw water turbidity in water supply system. Each water station under the jurisdiction of cold rolling water treatment workshop of Wisco Energy Complex Plant is equipped with multiple quartz sand or multi-medium filters. When the filter is running, the suspended matter in the raw water is intercepted and absorbed by the filter material layer and continuously accumulates in the filter material layer. The pores of the filter layer are gradually blocked by dirt, and the filter cake is formed on the surface of the filter layer. The filter head loss is increasing, and the flow rate and filter index are reduced. In 2015, a new filter backwash water reuse treatment system was set up at each water station in the cold rolling water treatment workshop to reduce fresh water consumption. Because the existing filter backwashing control mode is designed in accordance with the direct discharge of backwashing water, its automatic backwashing frequency does not match the processing capacity of the new backwashing water system, resulting in the backwashing water recycling system cannot run continuously and stably, the effluent turbidity is not up to standard, and the recycling effect of backwashing water is not good.

1. The filter of water supply system has an automatic backwashing process

The automatic backwash control of the filter control system can only be manually started once every 24h by monitoring the upper machine. Because different filter groups need different backwashing frequencies, the backwashing frequency of the filter group in turbidity cycle is higher, which is washed twice a day, while that of the filter group in clean cycle is once a day. If there are fewer filters and the backwashing frequency is low, take 4 filters as an example, the interval time between each filter reaches 6h, which affects the continuous operation of the water reuse system. If there are more filters and backwashing is frequent, it is impossible to automatically complete backwashing of all filters within 24h. If one backwashing cycle is set to 24h by modifying the interval time, the backwashing interval time is short and does not meet the treatment capacity of the reuse water system.

2. Existing problems and improvement plans of filter process

2.1 Existing Problems

The cold-rolled water treatment plant of Wisco Energy Complex includes cold-rolled water stations No. 1, No. 2, No. 3, No. 4 and silicon steel No. 2, No. 3, No. 4 and No. 5. According to the original filter automatic backwashing control mode, can only be manually started once every 24h automatic backwashing, if there are only 4 filters, the backwashing interval between each filter will reach 6h, so that the backwashing water treatment system is often idle, unable to run continuously, the production indicators such as integrated water purifier decrease, water turbidity increase and fluctuation, and can not discharge sludge normally; If there are more than 10 filter groups or the backwashing frequency is too high, the backwashing interval will be too short, which will not only cause the backwashing displacement to exceed the local recycling treatment capacity of the water station, but also cause the loss of a large amount of fresh water, and even cause the overflow of the collection pool.

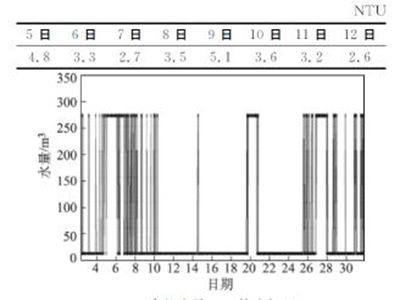

Taking cold rolling No. 1 water station as an example, the effluent turbidity of its integrated water purifier in May 2016 is shown in Table 1, and the water refill record is shown in Figure 1. Referring to Table 1 and Figure 1, the turbidity of the effluent of the integrated water purifier fluctuates greatly and is often higher than 3NTU (the design index should be less than 3NTU). The frequency of water replenishment is higher and the amount of water replenished is larger.

Table 1 The effluent turbidity of the integrated water purifier in May 2016

FIG. 1 Water refill record of a cold rolling station in May

2.2 Improvement Plan

Modify the filter automatic operation program, so as to realize the filter of water station automatically start backwashing at regular intervals every day, and control the total backwashing time, the number of automatic backwashing stations and the interval time of single backwashing. On the premise of ensuring the backwashing of all on-line filters within one backwashing cycle, make each backwashing interval adapt to the backwashing water treatment capacity, and ensure the continuous and stable operation of the backwashing water treatment system. And control the backwash water and displacement within the local backwash water treatment capacity of the water station, to avoid backwash water collection pool overflow or a large number of new water.

1) The automatic operation of the filter in each water station can be set to start automatically at different time points every day. If the last backwashing cycle is not completed, continue to complete the last backwashing. After each start, only one cycle is backwashing, and the total backwashing time and the number of backwashing stations can be set;

2) The on-line filter can be programmed into the automatic operation program, and the offline filter can be operated manually or out of service for maintenance;

3) After the on-line filters are sorted manually, they can be automatically backwashed in order. The backwash interval can be set automatically or manually, so that the backwash cycle of the filter can be adapted to the water treatment capacity and operation cycle of the water station.

3. Realize the improvement and effect of technological process

The control system of each water station in cold rolling water treatment workshop is not the same. Taking cold rolling No. 1 water station (PLC is a complete set of Siemens products, the upper computer monitoring software is Siemens WINCC7.0) as an example, the paper introduces how to optimize the control program, so as to realize the filter group timing automatic operation.

3.1 Improvement of process flow

1) Figure 2 shows the filter automatic operation interface. In the monitoring screen, set whether to add automatic backwashing and backwashing serial number of each filter by filling the blank, and can be arbitrarily set in the monitoring screen to complete the total time of one and one filter backwashing, to realize the control of the total length of automatic backwashing time.

2) According to the setting of the monitoring screen, complete the total time of one backwash of all filters, which can be obtained by the formula: single backwash time of a single filter = drainage time + air wash time + mixed wash time + standing time + forward wash time

(1) Backwashing interval of each filter = (total backwashing time - single backwashing time)/number of backwashing stations of on-line filter

(2) Calculate the backwash interval, and the logic of its control program is shown in Figure 3. Take a cold rolling station as an example. There are four filters in a cold rolling water station, and its backwash water treatment cycle is shown in Figure 4. A single washing process generates 300m3 backwash water, all of which is discharged into the collection tank. While the lifting pump of the collection tank has a maximum drainage capacity of 150m3/h during normal operation (one for use and one for standby), it takes more than 2h for all the backwash water from a single filter to be discharged once. It takes time from discharging the collection tank to entering the integrated water purifier. Meanwhile, the processing capacity of the integrated water purifier is 150m3/h, and 2h is needed to treat all the drainage of a single backwash. The sum of the backwashing time and backwashing interval of a single filter should not be less than 2h. The backwash water treatment cycle is shown in Figure 4.

3) According to the operator set time, start the filter automatic backwash every day. A window for setting startup time is added to the monitoring screen of the upper computer. The operator sets the self-starting and backwashing time of the filter every day, and then transmits the set time to PLC; Call OB block in PLC program, according to the set time, run the OB block regularly every day, in order to start the filter automatic backwash function. Filter timing automatic backwashing logic is shown in Figure 5.

3.2 Implementation Effect

Taking a cold rolling station as an example, the effluent turbidity of the integrated water purifier in July 2015 is shown in Table 2, and the supplementary water volume in July is shown in Figure 6. It can be seen from the comparison that the amount of new water added and the frequency of replenishing water decreased significantly after the function of backwashing timing and self-starting of the new filter group, and the turbidity index after backwashing drainage treatment was lower than 3NTU, which is better than the turbidity requirement of supplementary water quality in the Code for Design of Circulating Cooling Water Treatment (GB50050-2007).

4 Conclusion

By improving the filter automatic backwashing program, a new automatic timing backwashing function is added. The number of backwashing stations can be set arbitrarily and the total length of backwashing time can be controlled. The automatic timing backwashing of the filter group in the cold rolling water treatment workshop can be realized. Reduce new water consumption and production cost of tons of steel. The improved control mode has been extended to several water stations in cold rolling water treatment workshop of Wisco Energy Complex, and the operation effect is good.

| Previous:Application of dry fog dust suppression device in air dust removal in port area | Next:Application of dry fog dust suppression device in air dust removal in port area |

TEL

TEL

PRODUCTS

PRODUCTS

SOLUTION

SOLUTION

CONTACT

CONTACT