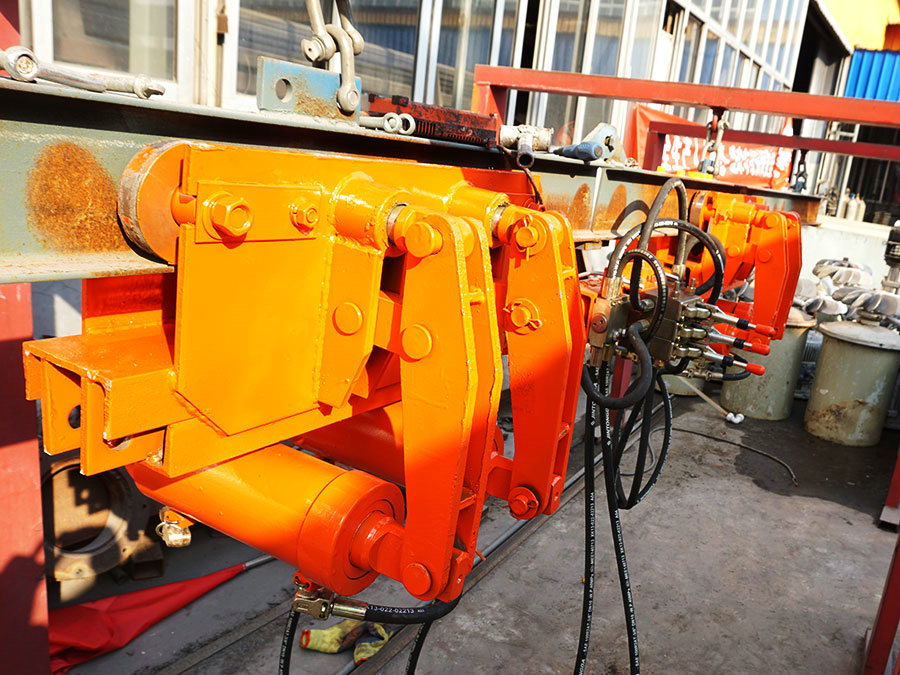

The application range of mine cable monorail crane

Instructions for use and operation

(1) Usage habits: The brake can be placed in the middle of the cable dolly or at the end (in the direction of shearer) according to different usage habits of users. When used at the end, only a cable dolly is set behind the brake to be rigid connected with the brake. With each advance of the fully mechanized mining face, the propulsion cylinder should be operated continuously. When used in the middle, the car connected with two brakes is rigidly connected with the brake. In the coal face - side car, a rigid rod (user provided) is used to connect the end car with the tail of the scraper conveyor. With the passage of the scraper conveyor, the rear cable car is automatically pushed, and the cable car is reduced to a very short distance. The power station needs to be moved forward when the section of cable is gradually straightened and the whole trolley is shortened to a very short distance. This method of use has fewer operation times and less frequent movement.

(2) Operation: First of all, the cables to be dragged are hung one by one to each cable trolley in a large distance, and the excess cables are placed on the special cable trolley on the floor of the roadway. With the continuous advance of the fully mechanized working face, when the cable needs to be pulled, the control valve handle is operated, the piston rod of the propulsion cylinder is extended, and the front brake and the cable trolley are pushed to move one step (800) in the direction of the power station. After the push cylinder reaches the stroke, the control valve handle is reversely operated, and the propulsion cylinder pulls the rear brake forward to follow up - one step. With such repeated operations, it can move up to 50 meters. When the cable trolley reaches close spacing, the substation needs to be moved. When moving the power station, the power station and the end brake are connected with steel wire rope. With the movement of the power station, the cable trolley and cable are gradually extended.

(3) The function of stopping and retracting cable trolley is to prevent the brake failure in the uphill section, and the cable trolley will reverse back.

| Previous:The introduction of mist machine | Next:The introduction of mist machine |

TEL

TEL

PRODUCTS

PRODUCTS

SOLUTION

SOLUTION

CONTACT

CONTACT